How Are Smartwatches Made? A Step-by-Step Guide

Smartwatches have revolutionized the wearable technology market, offering consumers a blend of style, functionality, and connectivity. As a business owner, distributor, or e-commerce seller, understanding the intricate process behind their manufacturing can provide you with a competitive edge.

Here’s a comprehensive step-by-step guide to help you navigate the smartwatch manufacturing landscape efficiently.

From design and component sourcing to assembly, quality control, and shipping, every stage plays a crucial role in delivering a high-quality product to the global market.

Understanding these processes ensures you make informed decisions, build reliable partnerships, and meet your customers’ expectations effectively.

Why Should You Understand the Smartwatch Manufacturing Process?

As a business owner, distributor, or e-commerce seller, understanding how smartwatches are manufactured is not just a nice-to-have—it’s a strategic advantage.

Knowing the process helps you select the right suppliers, reduce risks, and ensure the products meet market demands.

The Strategic Benefits of Understanding the Manufacturing Process

-

Supplier Evaluation

Not all suppliers are created equal. By understanding the steps involved in manufacturing smartwatches1, you can:- Identify if a supplier truly has the capability to deliver.

- Spot red flags like vague answers, incomplete processes, or lack of certifications.

This knowledge allows you to avoid unreliable partners and wasted investments.

-

Improved Communication

When you understand terms like prototyping, assembly lines, or quality control testing, you communicate with manufacturers clearly and confidently. This minimizes misunderstandings, avoids costly mistakes, and ensures production stays on schedule. -

Cost Management and Risk Reduction

Manufacturing smartwatches involves multiple stages, from sourcing components to final packaging. Without understanding these stages, you might miss hidden costs or production delays. Knowing the process helps you:- Identify areas where costs can be optimized.

- Negotiate more effectively on pricing and timelines.

- Mitigate risks like poor quality, missed deliveries, or hidden fees.

-

Product Differentiation

Customers today demand not just features but also quality and style. If you understand the manufacturing process, you can:- Customize products to match your market’s needs.

- Collaborate with suppliers on unique designs, features, or branding.

For instance, if fitness tracking and battery life are priorities in your market, you can work with manufacturers to focus on those during production.

-

Building Customer Trust

Knowledge breeds confidence. When you know exactly how your smartwatches are made, you can answer customer questions confidently, such as:This transparency helps build trust, which is critical for maintaining long-term customer relationships.

A Practical Scenario

Let’s say you’re sourcing smartwatches for your e-commerce store. One supplier offers watches at a very low price but is vague about their testing processes. Another supplier outlines every stage: design, component sourcing, assembly, and quality testing, and backs it with certifications like CE and FCC3.

If you know the manufacturing process, you’ll immediately spot the difference. Supplier transparency signals reliability, and you’ll avoid the common pitfalls of low-quality products, delayed shipments, and customer complaints.

In short, understanding the smartwatch manufacturing process gives you the power to make informed decisions, minimize risks, and create a product that aligns with market expectations. That’s not just good business—it’s smart business.

How Do Manufacturers Design and Prototype Smartwatches?

The design and prototyping phase is where every smartwatch begins to take shape. This stage determines not only how the product will look but also how it will function, feel, and perform in real-life conditions.

Manufacturers combine creativity, engineering, and precision to design prototypes that align with market demands while maintaining production feasibility.

Step 1: Market Research and Concept Development

The process starts with market research. Manufacturers and their clients analyze trends, target customer preferences, and competitor offerings to define the smartwatch’s concept. Key considerations include:

- Target Audience: Are the smartwatches designed for fitness enthusiasts, business professionals, or outdoor adventurers?

- Core Features: Health monitoring, fitness tracking, calls and notifications, GPS, or advanced apps?

- Aesthetic Style: Sleek and minimal, sporty, or rugged?

- Price Point: Balancing features with affordability to match target markets like wholesalers or distributors.

For example, a smartwatch designed for young fitness enthusiasts may include vibrant colors, lightweight materials, and robust health tracking sensors, while one for professionals may focus on a sleek design and long battery life.

Step 2: Industrial Design and 3D Modeling

Once the concept is clear, designers create detailed 3D models using advanced software like CAD (Computer-Aided Design)4. At this stage:

- Form and Dimensions: Engineers finalize the size, shape, and materials of the watch body and straps.

- Component Integration: The housing must accommodate essential parts like sensors, displays, batteries, and circuit boards.

- User Interface (UI): Designers outline the watch’s interface, focusing on intuitive usability for end users.

Importance of 3D Models

3D modeling bridges the gap between creativity and production feasibility. It ensures the design is aesthetically appealing while being functional and practical to manufacture.

Step 3: Functional and Physical Prototypes

Prototypes are the heart of the design stage. Before mass production, manufacturers test both the functionality and physical durability of the design. This involves creating two types of prototypes:

-

Functional Prototypes

These prototypes focus on the smartwatch’s internal systems, including the PCB (Printed Circuit Board)5, battery, sensors, and connectivity. Engineers ensure:- Processors handle multiple tasks without lag.

- Sensors like heart rate and step counters provide accurate readings.

- Bluetooth, GPS, and other connectivity features function seamlessly.

-

Physical Prototypes

Physical prototypes evaluate the external components. This includes:- Comfort: Testing how the watch feels on the wrist over extended wear.

- Durability: Assessing resistance to scratches, water, and drops.

- Weight and Materials: Ensuring the materials are lightweight yet sturdy.

Step 4: Prototype Testing and Refinement

No design is perfect in the first round. Prototypes undergo multiple rounds of testing to identify flaws and make improvements:

- Battery Life Testing: Engineers optimize battery usage to ensure longevity.

- Sensor Accuracy: Comparing real-world data from sensors with expected results.

- Usability Testing: Assessing how easily users interact with the watch interface.

- Stress Testing6: Simulating real-world conditions like extreme temperatures, water exposure, or mechanical impact.

Based on feedback, manufacturers refine the design by adjusting materials, improving software, or reworking the internal layout of components. For example, if a sensor fails to perform accurately, engineers reposition it or source an upgraded version.

Step 5: Final Design Approval

Once the prototypes pass all tests, the final design is approved. Manufacturers prepare for mass production by documenting:

- Bill of Materials (BOM): A complete list of components needed for production.

- Production Layout: Plans for integrating components on assembly lines.

- Quality Standards: Specifications to ensure every watch meets defined standards.

This stage bridges the gap between design and production, setting the foundation for large-scale manufacturing.

Why Does the Design and Prototyping Stage Matter to You?

For distributors, wholesalers, and e-commerce sellers, understanding the design process helps you:

- Customize Products: Collaborate with manufacturers to create unique, market-ready designs.

- Evaluate Costs: See where design choices impact production costs and pricing.

- Ensure Market Fit: Confirm the product meets your audience’s needs before committing to large orders.

By knowing how manufacturers design and prototype smartwatches, you can confidently choose products that align with your business goals while meeting customer expectations.

Where Do Smartwatch Manufacturers Source Their Components?

The quality and performance of a smartwatch heavily depend on its components, which are sourced from specialized suppliers worldwide. Manufacturers carefully choose these components to ensure durability, accuracy, and compliance with international standards.

Knowing where and how these components are sourced allows you to evaluate supplier reliability and understand the value behind the product.

Key Components in Smartwatches and Their Sources

Smartwatches are a blend of advanced electronics, precision hardware, and software integration. Each part comes from specialized suppliers with expertise in specific areas. Below are the primary components and where manufacturers typically source them:

| Component | Function | Primary Sourcing Regions |

|---|---|---|

| Processor (CPU) | Powers the watch, processes data, and runs software. | USA (Qualcomm), China (HiSilicon), Taiwan, China (Realtek) |

| Sensors | Tracks health data: heart rate, SpO2, steps, etc. | Germany (Bosch), Japan, China |

| Microphone | Enables voice commands and Bluetooth calling. | China, Japan |

| Speaker | Delivers sound for calls, notifications, and alarms. | China, South Korea |

| Bluetooth Modules | Provides wireless connectivity for data syncing. | USA (Qualcomm), China (Realtek) |

| AMOLED/LCD Displays | Provides visuals and touch responses. | South Korea (Samsung, LG), China |

| Gorilla Glass | Protects displays from scratches and impact damage. | USA (Corning Incorporated) |

| Batteries (Lithium-ion) | Powers the smartwatch for extended use. | China, South Korea |

| Straps and Housing Materials | Provides durability, comfort, and style. | China, Southeast Asia |

In-Depth Look at Critical Smartwatch Components

1. Processor (CPU)

The processor is the heart of the smartwatch, responsible for powering applications, handling multitasking, and optimizing energy consumption.

- Qualcomm Snapdragon Wear: Ideal for high-end smartwatches, offering multi-tasking and energy optimization.

- HiSilicon (Huawei): Known for efficient, mid-range processors.

- Realtek: Popular for cost-effective smartwatches, balancing price and reliability.

Manufacturers select processors based on price and performance7, ensuring they meet the target audience’s expectations.

2. Health and Activity Sensors

Reliable health sensors define the smartwatch’s value for fitness and health-conscious users:

- Heart Rate Monitors and SpO2 Sensors: Trusted suppliers like Bosch (Germany) ensure accuracy and durability.

- Motion Sensors8: MEMS technology integrates accelerometers and gyroscopes for precise activity tracking.

3. AMOLED Displays with Gorilla Glass

AMOLED displays deliver high contrast and vibrant visuals. Leading suppliers include Samsung and LG (South Korea). To protect these displays:

- Corning Gorilla Glass9: Ensures scratch resistance, lightweight strength, and durability.

High-end smartwatches feature AMOLED screens protected by Gorilla Glass to appeal to premium markets.

Challenges in Component Sourcing and Manufacturer Solutions

-

Global Supply Chain Disruptions

- Solution: Diversify supplier networks and maintain stock reserves for critical components.

-

Quality Variability

- Solution: Work with certified suppliers like Bosch, Realtek, and Corning. Conduct regular inspections to ensure quality consistency.

-

Cost Fluctuations

- Solution: Negotiate long-term contracts with suppliers and balance cost-effective and premium components.

Why Component Sourcing Matters for Business Owners

For distributors, wholesalers, and e-commerce sellers, understanding the sourcing process provides several advantages:

- Supplier Confidence: Assess whether manufacturers use high-quality components.

- Market Positioning: Justify pricing for premium or cost-effective products.

- Reduced Risks: Ensure compliance with international certifications like RoHS, CE, and FCC.

By understanding where smartwatch components come from, you can make more informed decisions, ensuring the products you sell meet both customer and market expectations.

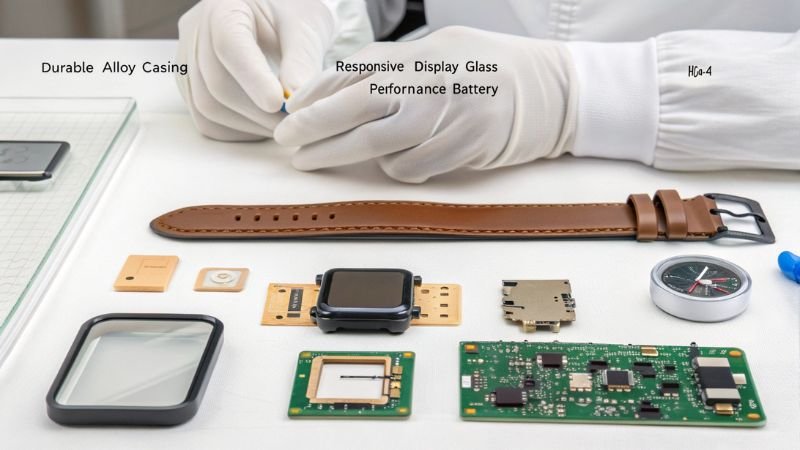

What Happens During the Assembly and Production Stage?

The assembly and production stage is where smartwatches transition from components into fully functional, market-ready products. This process integrates high-precision technology, skilled manual labor, and rigorous quality checks to meet customer expectations for durability, performance, and aesthetics.

For business owners, importers, and distributors, understanding this stage allows you to evaluate a supplier’s production capabilities, delivery reliability, and ability to scale for large orders—all critical factors for success in the competitive smartwatch market.

Step-by-Step Breakdown of the Smartwatch Assembly Process

1. Component Preparation and Pre-Assembly Inspection

Before assembly begins, all components—such as the processor, display, battery, sensors, and casing—are prepared and inspected. Manufacturers use automated systems and manual checks to ensure:

- Component Quality: Incoming parts are verified for defects.

- Batch Consistency: Components meet pre-defined quality and specification standards.

2. Printed Circuit Board (PCB) Assembly

The Printed Circuit Board (PCB) is the heart of a smartwatch, connecting the processor, sensors, Bluetooth module, and battery. Manufacturers use Surface Mount Technology (SMT) for precise and efficient PCB assembly10.

- Step 1: Solder Paste Application

- Step 2: Pick-and-Place Assembly

- Step 3: Reflow Soldering

- Step 4: Inspection (Automated Optical Inspection and X-ray tests).

Why It Matters: A single loose connection or error can render the smartwatch non-functional.

3. Component Integration and Assembly

After PCB assembly, the smartwatch’s physical parts are integrated step by step:

- Display Attachment: AMOLED or LCD screens are installed, often protected with Gorilla Glass.

- Battery Placement: Compact lithium-ion batteries are connected securely.

- Sensor Installation: Heart rate, GPS, and motion sensors are aligned precisely.

- Casing Assembly: Materials like stainless steel, aluminum, or plastic ensure durability and water resistance.

4. Software Installation and Calibration

- Firmware Installation: Core software enables essential functions.

- Sensor Calibration: Ensures accuracy in heart rate, SpO2, and motion tracking.

- Connectivity Testing: Bluetooth and Wi-Fi modules are fine-tuned for stable performance.

5. Quality Control During Assembly

To ensure reliability, smartwatches undergo rigorous quality control tests11:

- Functional Testing: Touch screens, sensors, and connectivity features are verified.

- Durability Testing: Drop tests, water resistance, and extreme condition simulations.

- Visual Inspection: Manual and automated checks for cosmetic defects.

Automation vs. Manual Processes

| Process | Automation | Manual Intervention |

|---|---|---|

| PCB Assembly | SMT pick-and-place machines | AOI and X-ray verification |

| Casing Assembly | Robotic fitting and sealing | Finishing and polishing |

| Sensor Calibration | Software-based alignment | Fine-tuning for sensor anomalies |

| Final Inspection | Camera-based automated scanning | Manual checks for cosmetic perfection |

Final Packaging and Shipment Preparation

Once quality control is complete, the smartwatches are:

- Packaged in protective boxes.

- Accessories like chargers and manuals are added.

- Branded with OEM packaging for customized orders.

- Shipped via reliable logistics partners.

Why Business Owners Should Understand the Assembly Stage

Understanding this stage helps you:

- Evaluate Production Capacity12: Assess whether factories can handle large orders efficiently.

- Ensure Reliability: Ensure rigorous quality control guarantees a premium product.

- Negotiate Timelines: Set realistic expectations for order completion and delivery.

At ViMiSMART, our factory’s 10 production lines combine automated precision with manual quality checks, enabling efficient production and strict quality control. We deliver trial orders in 7 days and larger OEM orders in 25 days, ensuring our clients stay ahead in competitive markets.

How Do Reliable Manufacturers Ensure Quality Control and Testing?

In the competitive smartwatch market, quality control (QC) and testing are critical for ensuring a product meets international standards, performs reliably, and satisfies end users. Reliable manufacturers implement rigorous quality control processes at every stage of production—from incoming materials to post-assembly checks.

For business owners, distributors, and e-commerce sellers, understanding how manufacturers maintain quality standards enables you to assess supplier reliability, reduce product returns, and build trust with your customers.

Quality Control Begins with Incoming Components

Reliable manufacturers understand that quality starts with components. High-performing smartwatches rely on processors, sensors, displays, and batteries functioning seamlessly. To ensure this, manufacturers implement:

-

Supplier Audits and Certifications

Manufacturers collaborate only with trusted, certified suppliers. Each supplier must provide:- Compliance Certifications: CE, FCC, RoHS, and ISO 900113.

- Batch Test Reports: Documentation confirming components meet predefined technical specifications.

For example, displays from Samsung or processors from Qualcomm must pass strict batch testing before entering the factory.

-

Incoming Inspection

Upon arrival, components undergo inspection to screen for defects. Key tests include:- Visual Inspection: Checking for scratches, damage, or misalignment.

- Electrical Testing: Ensuring components like batteries and PCBs function within defined parameters.

- Sample Testing: Random sampling of batches for deeper performance checks.

Why It Matters: Eliminating defective components early in the process prevents delays, rework, and wasted production costs.

Quality Control During Assembly

Reliable manufacturers implement multiple quality control checkpoints throughout the assembly process to catch issues before they escalate.

1. Precision in PCB Assembly

- Surface Mount Technology (SMT) ensures high-precision component placement on PCBs.

- After reflow soldering, manufacturers use Automated Optical Inspection (AOI) to detect:

- Soldering defects

- Misaligned components

- Short circuits

For complex components like microprocessors and Bluetooth modules, X-ray inspections identify hidden defects, ensuring every PCB meets operational standards.

2. Sensor Calibration and Functional Testing

Smartwatches rely on accurate sensors for health monitoring, fitness tracking, and navigation. Reliable manufacturers conduct sensor-specific testing, including:

- Heart Rate Sensors: Compared against control samples to ensure real-time accuracy.

- SpO2 Sensors: Tested for blood oxygen measurement precision under various conditions.

- Accelerometers and Gyroscopes: Calibrated to deliver correct step counts and movement tracking.

- GPS Modules: Tested outdoors to validate signal strength and location accuracy.

Functional Testing checks whether all features—like notifications, touchscreens, and Bluetooth pairing—work seamlessly under normal use conditions.

3. Assembly-Line Quality Audits

At each stage of assembly, workers and machines perform quality audits to catch inconsistencies early. Key processes include:

-

Display Integration: Screens are checked for:

- Brightness uniformity

- Pixel defects (dead spots)

- Touch responsiveness

-

Battery Integration: After placement, batteries are tested for:

- Voltage stability

- Charging capacity and overheating risks

-

Casing Assembly: Ensures housing and buttons align perfectly for durability and aesthetic appeal. Waterproof seals are inspected to guarantee compliance with IP67/IP68 ratings.

Post-Assembly Testing: Ensuring Full Functionality

Once the smartwatch is fully assembled, it undergoes comprehensive testing to confirm that all components work as expected. Key tests include:

1. Environmental Testing

Reliable manufacturers simulate real-world conditions to test durability and stability.

-

Water Resistance Tests:

- Watches are submerged in water to ensure compliance with waterproof standards (IP67 or IP68).

- Pressure tests simulate deep-water conditions to test seals.

-

Temperature and Humidity Stress Tests:

- Smartwatches are exposed to extreme temperatures (e.g., -20°C to 60°C) to verify performance in varying climates.

- Humidity chambers test resistance to moisture

2. Mechanical Durability Testing

- Drop Testing: Watches are dropped from multiple angles to ensure impact resistance.

- Button Life Testing: Buttons are pressed thousands of times to confirm durability and responsiveness.

- Strap Stress Testing: Straps are stretched and twisted repeatedly to simulate long-term wear and tear.

3. Battery and Charging Tests

Battery performance is crucial for user satisfaction. Manufacturers test:

- Battery Life: Smartwatches are run continuously to measure power consumption under normal and heavy use.

- Charging Cycles: Batteries are tested for efficiency across multiple charge cycles.

Software Testing and Calibration

Software plays a vital role in the smartwatch’s performance. Manufacturers ensure that:

- Firmware is Bug-Free: Watches run through automated tests to identify and resolve glitches.

- UI and UX Testing: Ensures smooth navigation, responsive touchscreens, and functional apps.

- Connectivity Verification: Bluetooth and Wi-Fi are tested to ensure stable connections.

Smartwatches are paired with devices (iOS and Android) to confirm compatibility and seamless data transfer.

Third-Party Testing and Certifications

Reliable manufacturers often partner with third-party testing agencies like SGS or TÜV Rheinland14 to verify product quality and safety. These tests include:

- Electromagnetic Compatibility (EMC): Ensures watches comply with CE and FCC standards for radio emissions.

- Material Safety: Compliance with RoHS regulations15 to avoid hazardous substances.

- Battery Safety: Ensures batteries meet international standards like IEC 62133.

Third-party reports build trust by providing objective proof of a product’s quality.

Final Inspection and Packaging

Before packaging, each smartwatch undergoes a final round of testing:

- Visual Inspection: Ensures no scratches, misalignment, or cosmetic defects.

- Functional Testing: Final verification of displays, sensors, buttons, and connectivity.

- Accessory Inclusion: Chargers, straps, and manuals are cross-checked for completeness.

Each watch is serialized with unique identification codes for traceability, helping manufacturers address any post-sale quality issues.

Why Quality Control and Certifications Matter for Business Owners

For distributors, wholesalers, and importers, partnering with a manufacturer that prioritizes quality control and certifications offers significant advantages:

- Reduced Risk: Products that meet international certifications are less likely to face customs issues or safety-related recalls.

- Market Access: Certified smartwatches can be legally sold in major markets like Europe, the USA, and Japan.

- Customer Confidence: Certifications build trust and reassure customers about safety, durability, and compliance.

- Competitive Edge: Offering reliable, tested smartwatches helps differentiate your brand in a crowded market.

For example, at ViMiSMART, our production process includes:

- Multi-stage QC checks, from components to final assembly.

- Compliance with global certifications like CE, FCC, RoHS, and UKCA.

- Third-party audits to validate our quality and safety claims.

Final Thoughts

Reliable manufacturers ensure quality control and testing at every stage—starting from component verification to final inspection—while adhering to global certification standards. This guarantees smartwatches that are safe, durable, and ready for international markets.

For business owners and distributors, partnering with a supplier who emphasizes rigorous QC processes and certifications minimizes risks, ensures compliance, and builds customer trust.

What Are the Raw Materials of a Smartwatch?

A smartwatch combines advanced technology, precision engineering, and carefully chosen raw materials to deliver functionality, durability, and style. Each component—from the display to the casing—relies on specific materials that define the product’s quality, longevity, and user experience.

For business owners, distributors, and importers, understanding the raw materials behind smartwatches allows you to assess product value, negotiate effectively, and cater to customer demands for premium or cost-efficient options.

Key Raw Materials in Smartwatch Manufacturing

Smartwatches consist of electronic components, structural materials, and accessories that work together to provide performance, aesthetics, and comfort. Below is a detailed breakdown of the essential raw materials used in each part of a smartwatch:

| Component | Raw Material | Purpose | Features |

|---|---|---|---|

| Processor and PCB | Silicon, Gold, Copper | Processing power and circuit connectivity | Highly conductive, durable |

| Sensors | Silicon, Glass, Platinum | Tracks health metrics like heart rate, SpO2 | Sensitive, precise, and stable |

| Display (AMOLED/LCD) | Glass, Indium Tin Oxide (ITO), Plastic | Provides visuals and touch interface | Scratch-resistant, high clarity |

| Display Protection | Corning Gorilla Glass, Sapphire Glass | Protects screen from scratches and impacts | Scratch-resistant, tough, transparent |

| Battery | Lithium-ion, Cobalt, Graphite | Provides energy storage for prolonged use | High energy density, lightweight |

| Casing (Housing) | Stainless Steel, Aluminum, Plastic | Provides structural support and aesthetic appeal | Durable, lightweight, anti-corrosion |

| Watch Strap | Silicone, Leather, Fluoroelastomer | Ensures comfort and durability | Flexible, sweat-resistant, durable |

| Microphone and Speaker | Metal Alloys, Polymer Materials | Enables Bluetooth calling and voice features | Acoustic precision, miniaturized |

1. Processor and PCB (Printed Circuit Board)

- Materials Used: Silicon, Gold, Copper

- Purpose: The processor is the brain of the smartwatch, and the PCB connects all components.

- Why These Materials?:

- Silicon: Ideal for integrated circuits due to its semiconductive properties.

- Gold and Copper: Highly conductive metals ensure seamless electrical connectivity.

2. Sensors

- Materials Used: Silicon, Glass, Platinum

- Key Sensors:

- Heart Rate Sensors: Use silicon photodiodes and glass lenses for optical light transmission.

- SpO2 Sensors: Depend on platinum for precision blood oxygen measurement.

- Accelerometers and Gyroscopes: Use MEMS (Micro-Electro-Mechanical Systems) technology.

High-quality materials ensure sensors deliver accurate and reliable data for health and fitness tracking.

3. Display and Display Protection

The display and its protection are vital for usability and longevity.

Display Materials:

- AMOLED: Composed of glass and Indium Tin Oxide (ITO) for vibrant, high-resolution visuals.

- LCD: Uses plastic substrates for cost-efficient, clear displays.

Display Protection:

- Corning Gorilla Glass16: Offers superior scratch resistance and impact protection.

- Sapphire Glass: Provides maximum hardness and transparency for premium watches.

Why It Matters: Durable displays reduce maintenance costs and enhance user satisfaction.

4. Battery

- Materials Used: Lithium-ion, Cobalt, Graphite

- Purpose: Provides efficient energy storage for prolonged smartwatch usage.

Why These Materials?:

- Lithium-ion17: High energy density ensures lightweight, long-lasting batteries.

- Cobalt and Graphite: Essential for battery stability and safety.

5. Casing and Straps

- Materials Used:

- Stainless Steel/Aluminum: Ensures durability and corrosion resistance.

- Silicone/Fluoroelastomer: Flexible, sweat-resistant materials for comfortable straps.

Why It Matters: The right materials improve wearability, durability, and visual appeal, enhancing user satisfaction.

6. Environmental and Certification Considerations

Reliable manufacturers ensure raw materials meet global safety and eco-standards:

- RoHS: Restricts hazardous substances in electronics.

- REACH: Guarantees chemical safety for materials.

- CE and FCC: Certify compliance with safety and performance standards.

Why Understanding Raw Materials Matters to Business Owners

For distributors, wholesalers, and e-commerce sellers, knowing the raw materials helps:

- Assess Quality: Identify premium materials like Gorilla Glass or Sapphire Glass.

- Position Products: Market watches for premium, mid-range, or budget buyers.

- Ensure Compliance: Meet global standards to avoid legal risks.

- Build Customer Trust: Promote durability and high performance to differentiate your brand.

For example, promoting stainless steel casing with Gorilla Glass displays highlights quality, while emphasizing polycarbonate and silicone options appeals to budget-conscious markets.

Final Thoughts

The raw materials of a smartwatch—from silicon processors to Gorilla Glass displays—determine its performance, durability, and price point. Premium materials like Lithium-ion batteries, stainless steel casings, and advanced sensors elevate the product, while cost-effective alternatives make it accessible to broader markets.

By understanding these materials, you can better evaluate suppliers, negotiate confidently, and meet customer expectations for quality and price.

What Should You Know About Packaging and Shipping Smartwatches?

Packaging and shipping play a critical role in the smartwatch supply chain. They ensure the product reaches customers intact, complies with global shipping regulations, and enhances the overall brand experience. Reliable manufacturers prioritize not only protective packaging but also efficient, compliant shipping methods to help business owners, distributors, and e-commerce sellers deliver value to their end customers.

For businesses, understanding this stage is essential to avoid product damage, reduce logistics costs, and create a strong impression on customers.

Key Objectives of Packaging and Shipping

- Protect the Product: Smartwatches are sensitive electronics, requiring protection against moisture, impacts, and temperature fluctuations.

- Branding and User Experience: Custom packaging enhances brand image and delivers a memorable unboxing experience.

- Global Shipping Compliance: Products must adhere to international regulations like UN3481 for lithium-ion batteries18 and CE/FCC labeling19.

- Cost Efficiency: Optimized packaging minimizes weight and dimensions, reducing shipping costs without compromising safety.

Packaging: Protecting Smartwatches During Transit

1. Inner Packaging: Product Protection

- Foam Inserts: Custom EVA foam keeps the smartwatch snug and absorbs shock.

- Anti-Static Bags: Prevent electrostatic discharge from damaging electronic components.

- Cushioned Cases: Soft cases or pouches protect accessories like chargers and straps.

2. Outer Packaging: Structural Protection

- Corrugated Cardboard Boxes: Durable yet lightweight to withstand impacts during transit.

- Rigid Boxes: High-end smartwatches use rigid packaging for a premium look and feel.

- Sealing Materials: Air cushions, bubble wrap, and reinforced tape ensure safety.

Custom Branding and Enhancing User Experience

- Branded Packaging: Add logos, taglines, and high-quality prints to distinguish your product.

- Accessory Organization: Neatly arrange smartwatches, chargers, and manuals with custom trays.

- Eco-Friendly Materials20: Recyclable or biodegradable packaging enhances brand reputation among eco-conscious customers.

- Extras for Engagement: Include thank-you notes, QR codes for manuals, or stickers to delight customers.

Ensuring Compliance with Global Packaging Standards

Smartwatch packaging must meet shipping regulations to avoid customs delays:

- CE Marking (Europe): Confirms compliance with EU safety and environmental standards.

- FCC Labeling (USA): Required for radio-frequency safety compliance.

- UN3481 for Lithium-Ion Batteries: Labeling and handling regulations ensure safe air and sea transport.

- RoHS Compliance: Packaging materials must be free of hazardous substances like lead and mercury.

- WEEE Directives: Promotes recycling and eco-friendly disposal of electronics and packaging.

Shipping: Managing Logistics and Timely Delivery

| Shipping Method | Best For | Lead Time | Considerations |

|---|---|---|---|

| Express Air Freight | Small orders, urgent needs | 5–7 days | Faster but costly |

| Sea Freight | Bulk shipments | 25–35 days | Cost-effective, slower |

| Rail Freight | Europe-Asia bulk transport | 15–20 days | Balance of speed and cost |

| Courier (DHL/UPS) | Samples, smaller batches | 3–7 days | Reliable and quick |

- Weight Optimization: Packaging is designed to reduce weight and minimize shipping costs.

- Palletizing: For bulk shipments, products are secured and shrink-wrapped on pallets for stability.

- Documentation: Includes packing lists, invoices, CE/FCC certifications, and certificates of origin.

Preventing Common Shipping Risks

Reliable manufacturers address key challenges during transit:

- Moisture Damage: Desiccants (silica gel) absorb humidity.

- Impact Damage: Multi-layered cushioning prevents shocks and vibrations.

- Customs Delays: Accurate documentation ensures smooth customs clearance.

- Battery Safety: Proper labels and handling protocols meet UN3481 standards for lithium-ion shipments.

Why Packaging and Shipping Matter for Business Owners

For business owners, understanding packaging and shipping ensures:

- Product Protection: Reduces damage, returns, and replacements.

- Enhanced Customer Experience: Well-branded, organized packaging impresses customers and boosts satisfaction.

- Compliance Confidence: Meeting CE, FCC, and UN3481 guidelines avoids delays and penalties.

- Cost Savings: Optimized packaging reduces shipping costs while maintaining protection.

- Global Reach: Efficient shipping methods ensure on-time delivery to any market worldwide.

Final Thoughts

Packaging and shipping are vital components of the smartwatch supply chain. From protective foam inserts to compliance with global regulations like UN3481 for lithium-ion batteries, reliable manufacturers ensure products are delivered safely, efficiently, and with a strong brand impression.

By understanding and prioritizing packaging and shipping, businesses can minimize costs, prevent damage, and enhance customer satisfaction—ensuring their smartwatches arrive in perfect condition, ready to impress customers globally.

Conclusion

Understanding the smartwatch manufacturing process helps business owners and sellers choose reliable suppliers, evaluate quality, and reduce risks. By knowing each step—from design and component sourcing to assembly, quality control, and packaging—you can confidently grow your business, ensuring that your products meet market demands and exceed customer expectations.

-

Understand the end-to-end workflow for smartwatch production, including design and assembly ↩

-

Understand the testing standards used to ensure smartwatches are durable and long-lasting ↩

-

Understand how CE and FCC certifications guarantee safety, compliance, and product reliability ↩

-

Learn how advanced software like CAD is used to create accurate smartwatch designs ↩

-

Discover why PCB (Printed Circuit Board) design is crucial for functionality and efficiency ↩

-

Discover the durability and stress testing methods used to ensure smartwatches meet quality standards ↩

-

Learn about the key regions and companies producing processors for smartwatches ↩

-

Explore trusted suppliers of sensors like heart rate monitors and SpO2 trackers for wearables ↩

-

Discover how Corning Gorilla Glass improves display scratch resistance and impact protection ↩

-

Discover how Surface Mount Technology ensures precise and efficient PCB assembly ↩

-

Learn about key testing methods that guarantee smartwatch durability and accuracy ↩

-

Explore how automation enhances production efficiency while manual checks ensure quality ↩

-

Discover why ISO 9001 certification is crucial for quality management and reliable suppliers ↩

-

Explore the role of third-party agencies like SGS and TÜV Rheinland in verifying product quality ↩

-

Understand RoHS standards and how they ensure the use of safe, eco-friendly components ↩

-

Learn how Corning Gorilla Glass enhances durability, scratch resistance, and display protection ↩

-

Understand the role of lithium-ion batteries in providing efficient and long-lasting energy ↩

-

Learn the safety regulations for shipping products containing lithium-ion batteries internationally ↩

-

Understand why CE and FCC compliance labels are essential for smooth customs clearance worldwide ↩

-

Explore how eco-friendly packaging enhances brand value and meets consumer sustainability demands ↩